- Management of original sources/place of origin

- Original sources we supply are wide-range and various.

- For Asia, our company handles Chinese, Korean, Taiwanese and Mongolian sources and for Europe, excellent ones from Hungary, Poland, France, Ukraine and Canada.

- Even though many companies sell low quality, cheap down from subtropical regions, our DIVO DOWN selects and produces high quality sources.

- Furthermore, more than 90 % of DIVO DOWN is produced from good sources raised at 40 – 52 degrees north latitude called the down belt.

- Because down clusters from original sources produced here have a bigger size, and a higher density and fill power than other areas, they show very superb thermal insulation and quality. The down is conducive to quality improvement of buyers’ apparel and bedding and going further, better winter life of consumers.

Main production place of DIVO DOWN

- Production item

- Our company does not spare investment in R&D on special processing technology to better basic and special down functions, aside from duck and goose down.

- Our company built production lines that meet such a purpose, supplying products to buyers which have gone through water repellent processing, heating down, DAPOLAN, sterilization, power processing, Teflon, color processing AND smell processing.

- Our company introduced automatic production system made by LORCH with world-renowned technology to produce best quality down.

- Using these advantages, our company has a network with foreign buyers including American and European buyers based on trust.

- 1. Exhaustive hygiene control by production stage

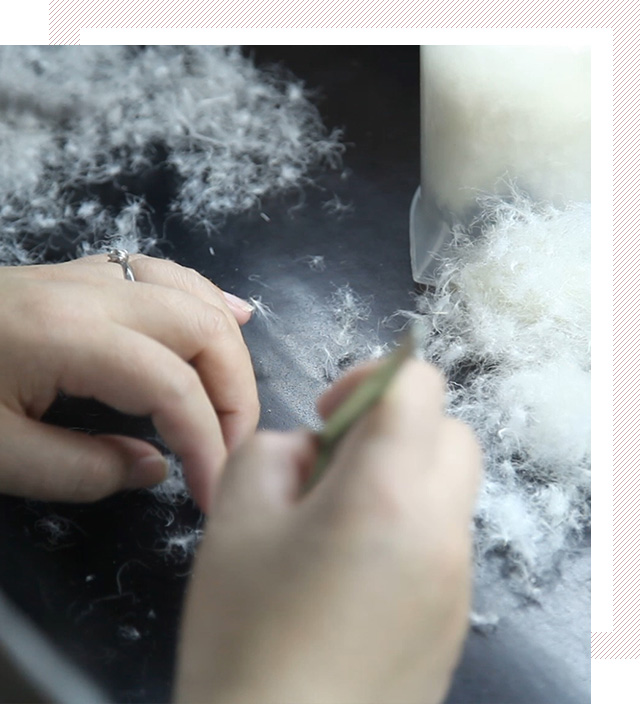

- Our company uses clean water and certified chemicals and prevents damage to human bodies with sterilization, and skilled workers control the whole process from production to shipment.

- 2. Strict inventory management

- Our company excludes conditions harmful to quality depending on grades and manages the best quality.

- 3. Down analysis before shipment

- 30 or so staff analyze down before shipment.

- 4. Request of down analysis from the KATRI

- Our company frequently requests down analysis from the KATRI after shipment.

- 5. Scientific waste water treatment facility

- Our company has a scientific waste water treatment facility to prevent environmental pollution.

Quality control

-

- Material

- Inspection

- (Composition/Down mixing rate)

-

- Washing

- Inspection

- (Composition/Down mixing rate)

-

- Sorting

- Inspection

- (Turbidity, composition/down mixing rate)

-

- Substandard quality

-

- Mixing

- Inspection

- (Composition/down mixing rate, fill power)

-

- Washing

- Inspection

- (Turbidity, composition/down mixing rate, fill power)

-

- Sorting

- Inspection

- (Turbidity, composition/down mixing rate)

-

- Quality check

-

- Shipment

KO

KO EN

EN CH

CH